The edge systems may decide what gets sent, where it gets sent and when it gets sent.

These systems may not send all data back to the cloud, but the data can be used to inform local machine behaviors as it is filtered and integrated. With edge computing and analytics, data is processed near the source, in sensors, controllers, machines, gateways, etc. This makes it essential that today’s automation assets, such as PLCs, be designed to leverage IIoT and the edge. These functions will end up where it makes most sense for them to be. As the digitization of industrial systems proceeds, so does analysis, decision-making, and control being physically distributed among edge devices, the network, the cloud, and connected systems, as appropriate. Edge computing and analytics are increasingly being located close to the machines and data sources. The growth of IIoT extends the edge to industrial devices, machines, controllers and sensors. But the question is what about the technology that is embedded into these new controllers that is enabling IIoT and pushing these new devices to the edge? And will this be a trend for future controllers? To address these market trends, Honeywell Process Systems introduced its new ControlEdge PLC, an IIoT-enabled controller that can act as an edge device.

They will also be capable of collaborating with powerful analytics tools, detecting anomalies in real time, and raising alarms so that operators can take appropriate actions. Besides providing control, these edge devices will securely collect, aggregate, filter, and relay data, leveraging their close proximity to industrial processes or production assets. One key part of this new infrastructure will be edge devices, which will include the latest generation of controllers, such as DCSs, PLCs and PACs. This will require the current plant information infrastructure to evolve. Data will be generated faster and in greater volume than ever before. IIoT is changing the way industrial organizations generate, collect, and analyze data.

Honeywell plc software serial#

At least one onboard serial interface (Saia PCD3.M5/6: 3×).Ethernet interface with all the important web/IT protocols, including those for PG5 communication.USB interface for configuration, programming and commissioning.The basic equation Saia PCD® = PLC + (web + IT) means that the conventional automation pyramid is becoming an open, transparent structure. Saia PCDs combine PLC functionality with innovative web and IT technology in an industrial quality system.

Honeywell plc software series#

It can be used for all device series (Saia PCD1, 2 and 3).

Honeywell plc software software#

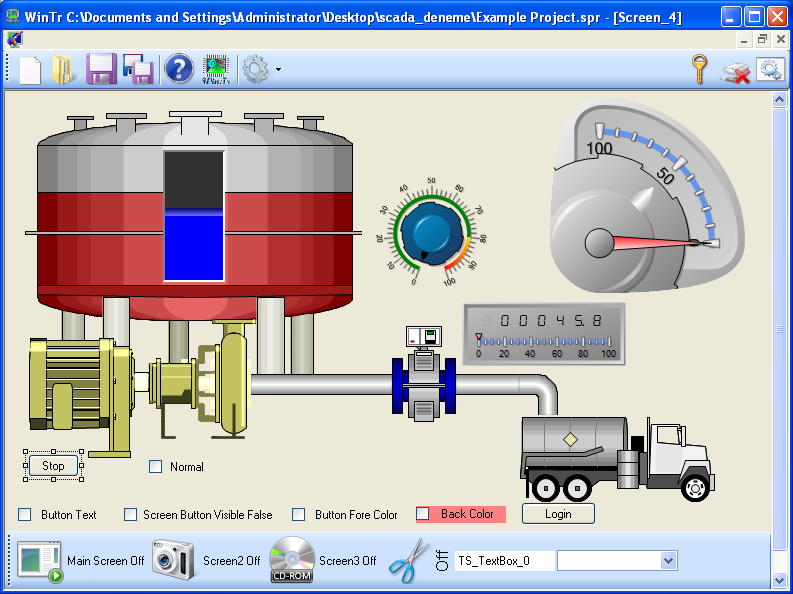

The application software can be simply and reliably adapted and expanded throughout its service life. Modular series consisting of industrial quality CPU, I/O and communication modules with a service life that will last for decades. Programmable for measuring, regulation and control devices. These PLC systems are manufactured in Switzerland with highest quality standards. These PLC are available with CPU redundancy, HMI & SCADA as well. G K Controls Private Limited offers Honeywell SBC range of Programming Logic Controller (PLC) for medium to large size of control and automation requirements of Honeywell make.

0 kommentar(er)

0 kommentar(er)